Finishes

Painted

The chains are covered with synthetic resin-based powder paint (for example epoxy powders), which adhere by electrostatic effect, and then passed into an oven where, thanks to a temperature of about 200°C, the paint first melts and then polymerizes perfectly adhering to the surface. Both processes are carried out to guarantee the chains greater protection from corrosion and from atmospheric or external agents.

Nickel Plated

The treatment consists in coating the chain with a thin layer of nickel which slows down the oxidation process in contact with atmospheric agents, as well as giving a more pleasant aesthetic appearance. Particularly used in ornamental chains with a maximum wire size of 6mm. This treatment will not preserve the article from the possible formation of rust; therefore, it is advisable to use it internally.

Brassed

The treatment consists in coating the chain with a thin layer of brass which slows down the oxidation process on contact with atmospheric agents, as well as giving a more pleasant aesthetic appearance. Particularly used in ornamental chains with a maximum wire size of 6mm. This treatment will not preserve the article from the possible formation of rust; therefore, it is advisable to use it internally.

Bronzed

The treatment consists in coating the chain with a thin layer of bronze which slows down the oxidation process in contact with atmospheric agents, as well as giving a more pleasant aesthetic appearance. Particularly used in ornamental chains with a maximum wire size of 6mm. This treatment will not preserve the article from the possible formation of rust; therefore, it is advisable to use it internally.

Brunished

The treatment takes place as for bronzing, by coating the chain with a thin layer of bronze, with the difference that it is left for a longer period. This treatment allows to slow down the oxidation process in contact with atmospheric agents, as well as giving a more pleasant aesthetic appearance. Particularly used in ornamental chains with a maximum wire size of 6mm. This treatment will not preserve the article from the possible formation of rust; therefore, it is advisable to use it internally.

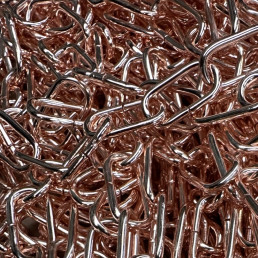

Coppered

The treatment consists in coating the chain with a thin layer of copper which slows down the oxidation process in contact with atmospheric agents, as well as giving a more pleasant aesthetic appearance. Particularly used in ornamental chains with a maximum wire size of 6mm. This treatment will not preserve the article from the possible formation of rust; therefore, it is advisable to use it internally.

High Thickness Galvanizing

The electrolytic galvanizing process guarantees greater protection and resistance to atmospheric agents by acting directly on the entire surface of the chain, especially on the contact parts of the rings. The yellow color typical of this finish is due to a final "passivation" treatment which gives it the final appearance.